Share Tree Planting Ceremony on Facebook

Share Tree Planting Ceremony on Linkedin

Email Tree Planting Ceremony link

2 March 2025

On a recent Councillor tour of the Gilmore Resource Recovery Centre, Mayor Julia Ham joined Resource Recovery Officer Martin and Valmar staff for a tree planting ceremony, symbolically ‘opening’ the facility and celebrating composting coming full circle—with compost now available for purchase.

Share SVC Launches Compost from FOGO Collections on Facebook

Share SVC Launches Compost from FOGO Collections on Linkedin

Email SVC Launches Compost from FOGO Collections link

27/11/24

Residents of the Snowy Valleys can now purchase high-quality compost made from their Food Organics and Garden Organics (FOGO) collections, with sales launching on 2 December 2024.

Read the full media release here.

Share Facility Fully Operational on Facebook

Share Facility Fully Operational on Linkedin

Email Facility Fully Operational link

23 May 2024

Our new, state-of-the-art organics processing facility is now complete and fully operational.

The project included the installation of the innovative Modular Aerated Floor (MAF) composting technology, a storage shed and associated road works and fencing.

The MAF system uses a series of pipes installed underneath the compost piles to aerate the compost and speed up the process, turning food and garden waste into rich compost in 12 weeks.

Since launching the kerbside Food Organics Garden Organics (FOGO) collections in August 2021, we've aimed to divert over 1,000 tonnes of organic waste from landfill each year. In the first two years, we successfully recovered 1,167 tonnes and 1,666 tonnes, reducing household landfill waste by 20%.

This new facility allows us to process and repurpose organic waste locally. By improving how residents sort their waste, we can ensure that more than half of our household rubbish is transformed into soil conditioning products for agriculture and horticulture. Continuous improvement in waste sorting habits from our community will help us achieve this goal.

We are currently trialling the compost in council parks and cemeteries, with plans to make it available to residents in the future.

Share FOGO Training on Facebook

Share FOGO Training on Linkedin

Email FOGO Training link

9 May 2024

Our FOGO team have been training in the operation of the Modular Aerated Floor (MAF) Composting technology at our Gilmore composting facility. The MAF system uses innovative composting technology, a series of pipes installed underneath the compost piles aerates the compost and speeds up the process. The technology turns food and garden waste into rich compost in 12 weeks.

We are currently trialling the compost in council parks and cemeteries, with plans to make it available to residents in the future.

Share New Weather Station on Facebook

Share New Weather Station on Linkedin

Email New Weather Station link

24 April 2024

The weather station at the Gilmore composting facility is now in operation. It will be used to measure atmospheric conditions like temperature, humidity, precipitation as well as wind speed and direction at the facility.

Share Exciting Updates on Facebook

Share Exciting Updates on Linkedin

Email Exciting Updates link

9 April 2024

Construction of our new, high-tech composting facility at Gilmore is gaining momentum. Here’s what we’ve been up to lately:

- Finished the culvert and creek crossing

- Completed site excavation, including stripping and compacting

- Constructed and lined the compost run-off dam

- Installed the power supply transformer

- Poured the slab for our storage shed and Gross Pollution Trap (GPT)

Next up we’ll be building the storage shed, installing the required weather station, and assembling the Modular Aerated Floor (MAF) Composting system.

Share Earthworks Underway on Facebook

Share Earthworks Underway on Linkedin

Email Earthworks Underway link

14 September 2023

Earthworks and the creek culvert installation works are underway at the Gilmore Organics Processing Facility site.

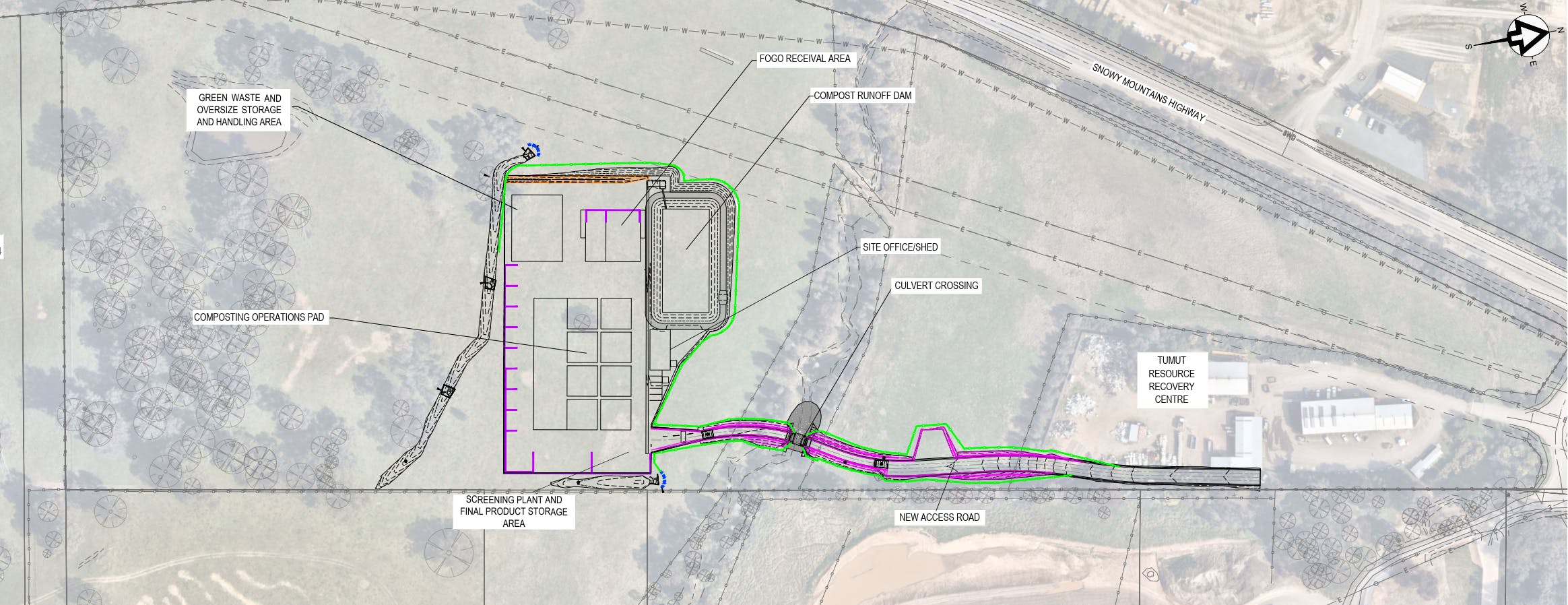

The site will be accessed through the Tumut Resource Recovery Centre. Construction of the access road into the facility requires installation of four precast concrete box culverts with wing walls and additional rock protection to control high water flows and protect channel banks around the existing creek.

Earthworks are also underway on the pad construction. The 145m x 62m pad area will be made of compacted clay with a gravel top surrounded by internal roads. The area includes a receiving pad and five composting stages for the Mobile Aerated Floor (MAF) processing operations.

The MAF system uses an innovative composting technology, a series of pipes installed underneath the compost piles aerates the compost and speeds up the process. The technology will be able to take food and garden waste and turn it into rich compost in 6-8 weeks.

Share New Organics Sorting Machine on Facebook

Share New Organics Sorting Machine on Linkedin

Email New Organics Sorting Machine link

3 August 2023

A new impressive piece of equipment which will play a vital role in council’s organics processing system is now onsite in Batlow where staff have been learning how to use it.

The Trommel Screen efficiently separates soil, sand, gravel, stones, green waste, wood chips, compost, recycled materials, and glass.

The curved cylinder screen spins to sort through the material. As it rotates, wet materials tumble around, while air is added to make the soil and mulch lighter and drier working to achieve the highest quality product.

Different screen sizes will be used to produce various end product consistencies from finer soil to chunky bark.

The machine can process 50m3/hour which is equivalent to around three full FOGO collection truck loads, plus, it runs on electricity and will be solar-powered when moved to its final home at the new Gilmore FOGO facility.

Share Progress for Local Organics Processing Facility on Facebook

Share Progress for Local Organics Processing Facility on Linkedin

Email Progress for Local Organics Processing Facility link

28 June 2023

Significant progress has been made on plans to construct an organics processing facility for the Snowy Valleys, including approval from Heritage NSW for an Aboriginal Heritage Impact Permit.

The new purpose-built facility, to be located south of the Tumut Resource Recovery Centre in Gilmore on the Snowy Mountains Highway, will enable Snowy Valleys Council to locally process and repurpose organic waste generated by the community.

During the early planning stages of the project, an extensive archaeological dig at the site uncovered a number of Aboriginal objects, requiring Council to work closely with Heritage NSW to obtain an Aboriginal Heritage Impact Permit allowing safe and approved construction to continue while ensuring designated areas are protected.

To read the full media release click here.